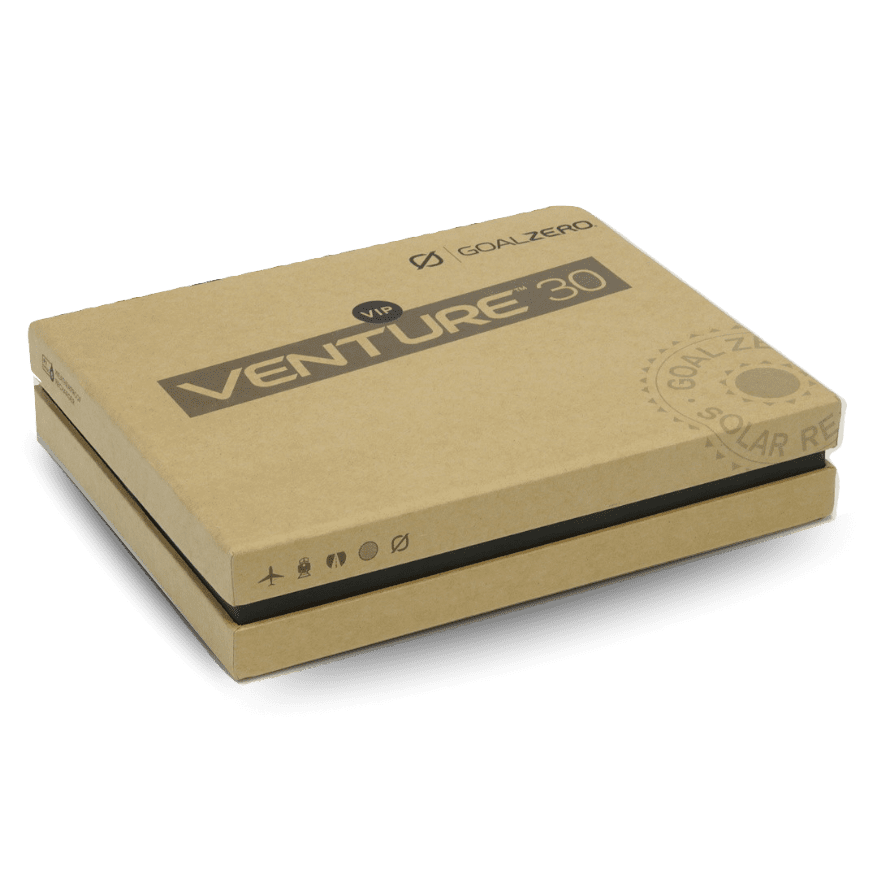

RIGID BOXES

Wynalda Packaging is a custom rigid box manufacturer, specializing in luxury packaging for brands across a variety of industries. Rigid set-up boxes can serve as a luxury packaging option for a variety of products.

FEATURES

SPECIALTY COATINGS

Add visual appeal and texture for a high quality finish.

FOIL

Cold foil application or hot foil stamping to add shine.

VARIABLE PRINTING

Print unique, personalized designs or serialized codes on each carton.

EMBOSSING

Amplify package texture with embossing or debossing.

Get Your Project Started

Specialty Coatings

Specialty coatings can be applied during printing to enhance both the visual appeal and functionality of packaging. Some of the most commonly used specialty coatings include Gloss, Matte, Soft-Touch, Pearlescent, Reticulating, and Spot UV. Whether using just one, or combining multiple specialty coatings, they can be used to add depth, texture, and protection to packaging, helping brands achieve a distinct, high-quality finish tailored to their unique needs and marketing position.

Foil

Foil adds a metallic effect that elevates your product’s perceived value and shelf appeal. There are two main techniques for incorporating foil into packaging: cold foil printing and hot foil stampings.

Cold foil printing is ideal for intricate details and vibrant metallic colors. It’s applied inline during the printing process and can be overprinted with inks to achieve a wide spectrum of metallic shades. This technique does not require additional post-press steps, which streamlines production and improves efficiency.

Hot foil stamping, on the other hand, offers unmatched richness and tactile dimension. Choose from a wide range of foils including golds, silvers, holographic foils, and extensive color options. Though more time-intensive, this method delivers crisp definition, texture, and lasting durability.

Variable Printing

With our Landa S11 digital offset press, we can print unique designs on every sheet, delivering full sheet-to-sheet variation at speeds comparable to traditional offset, without any loss in print quality. This opens the door to personalized packaging, version testing, serialized QR codes, and more.

Embossing & Debossing

Embossing and debossing add depth, texture, and tactile elements to designs, enhancing both visual and physical appeal. Embossing creates a raised effect, making specific design elements such as logos or patterns stand out. Debossing creates a recessed effect by pressing the design into the packaging’s surface, providing a subtle, sophisticated look that emphasizes detail and depth without necessarily catching light.

Get Your Project Started

Why Choose Custom Rigid Box Packaging?

STRENGTH & DURABILITY

Made of a dense chipboard, rigid boxes provide structural integrity.

UNBOXING EXPERIENCE

Custom rigid box packaging provides a premium unboxing experience for your customers.

PROFESSIONAL

Rigid boxes are perfect for kitting products/accessories into a single, professional and efficient solution.

PREMIUM QUALITY

Premium and luxury brands often choose a rigid box to communicate value and quality of their products and brand message.

Get Your Project Started

Sustainability

Rigid setup boxes offer sustainability benefits alongside their premium appearance and durability.

Often made from recycled chipboard and wrapped with paper, these boxes can be designed with fully recyclable components. Their sturdy construction also encourages reuse, making them a sustainable option for high-end packaging and gift sets.

At Wynalda Packaging, we offer FSC®-certified packaging produced with materials sourced from responsibly managed forests, recycled materials, and other controlled sources.

(FSC® C149826)

Rigid Box Projects

Made In The USA, Start to Finish

From graphic and structural design to press, and die cutting to gluing, we do it all in-house at our 400,000+ sq. ft. facility, located just north of Grand Rapids, MI.

Trusted Rigid Box Supplier To…

Consider All Options…

Make sure to check out Molded Pulp & Folding Cartons to see which packaging type fits your project best.

Molded Pulp

Folding Cartons