Sustainable Package Design

As businesses and consumers are becoming more environmentally conscious, sustainable package design has become a priority for brands looking to reduce their environmental footprint. By incorporating eco-friendly materials, optimizing structural designs, and minimizing waste, companies can create packaging solutions that are both functional and sustainable.

Eco-Friendly Material Selection

A fundamental consideration when developing sustainable packaging solutions is the selection of materials being used.

- Recycled Materials: Choosing paper-based or plastic options composed of recycled content helps minimize environmental impact by reducing waste and conserving natural resources.

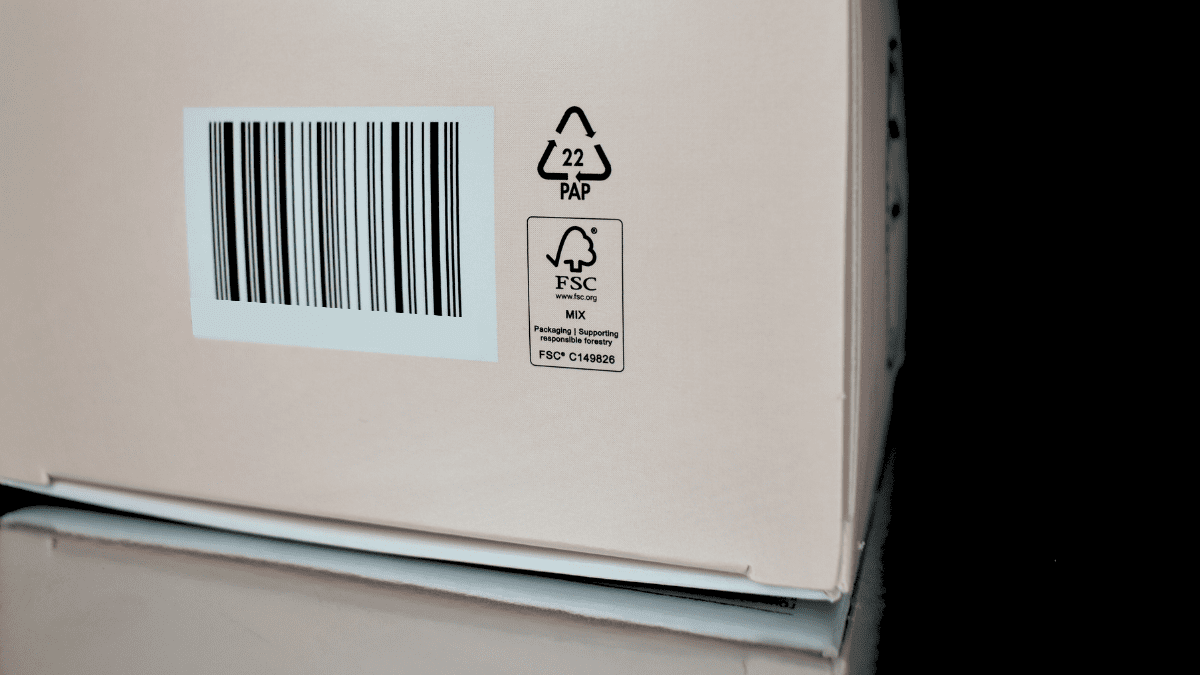

- Recyclability: Utilizing a single material like paperboard or PET, or easily separable materials that are compatible with existing recycling processes contributes to a circular economy.

- Renewable Resources: Sourcing packaging materials from renewable resources like FSC® or SFI® certified paperboard supports responsible forestry practices. (FSC® C149826)

Box Materials

Common types of box packaging made from sustainable materials include:

- Paperboard Folding Cartons: These cartons are lightweight and can be made from recycled or sustainably sourced paperboard.

- Rigid Set-Up Boxes: Often used for premium products, these boxes are made of recycled chipboard, offering a luxurious yet sustainable choice.

- Corrugated Boxes: Made with high recycled content and designed for durability, corrugated packaging is a staple for sustainable packaging.

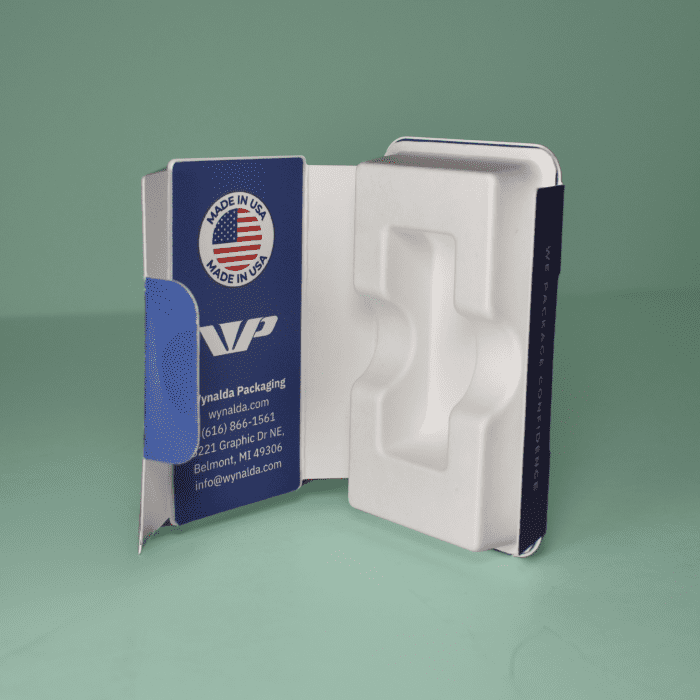

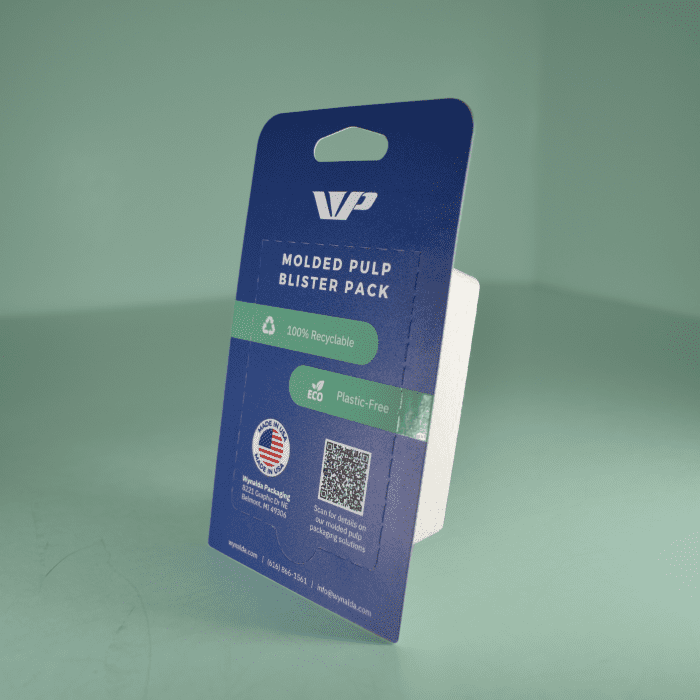

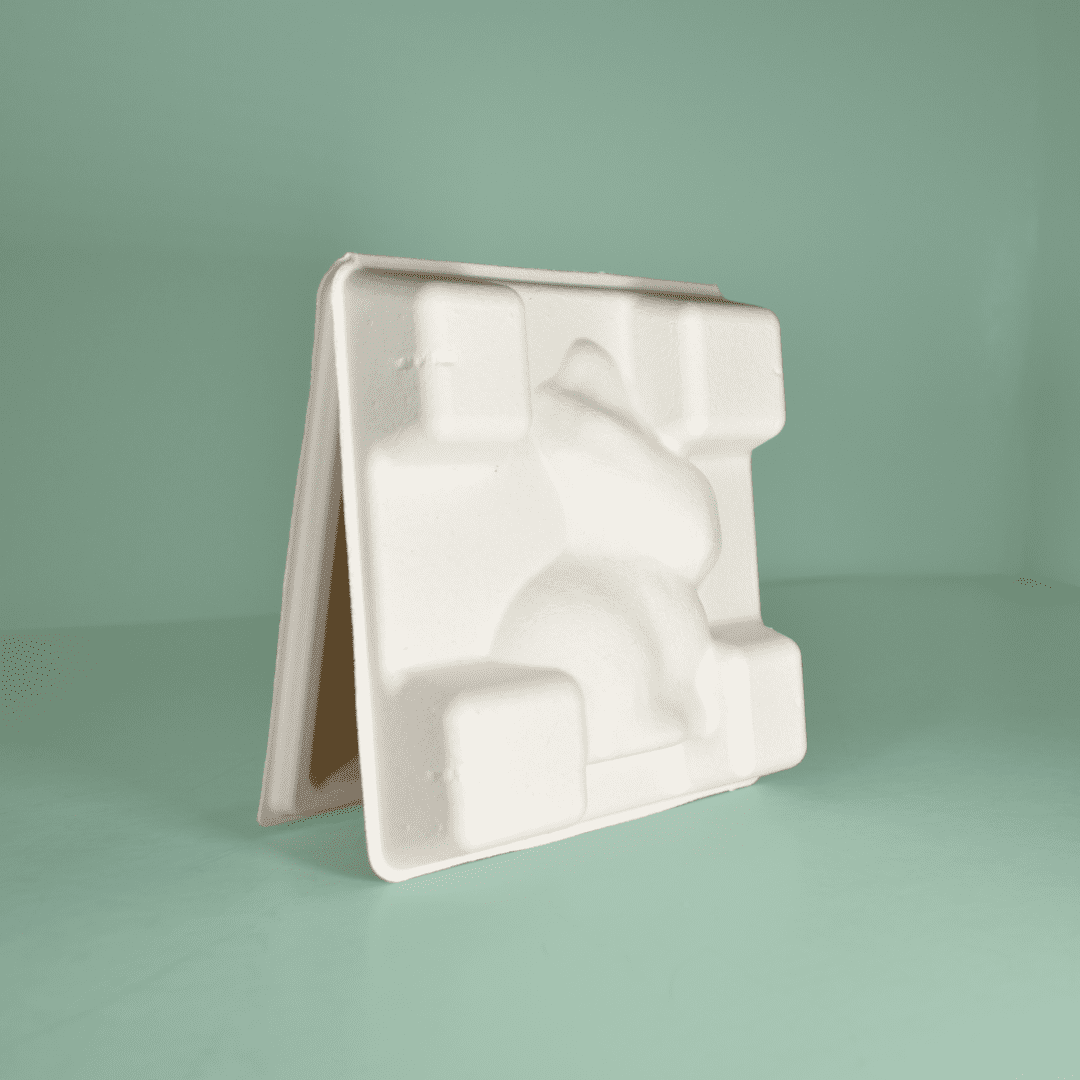

Insert Materials

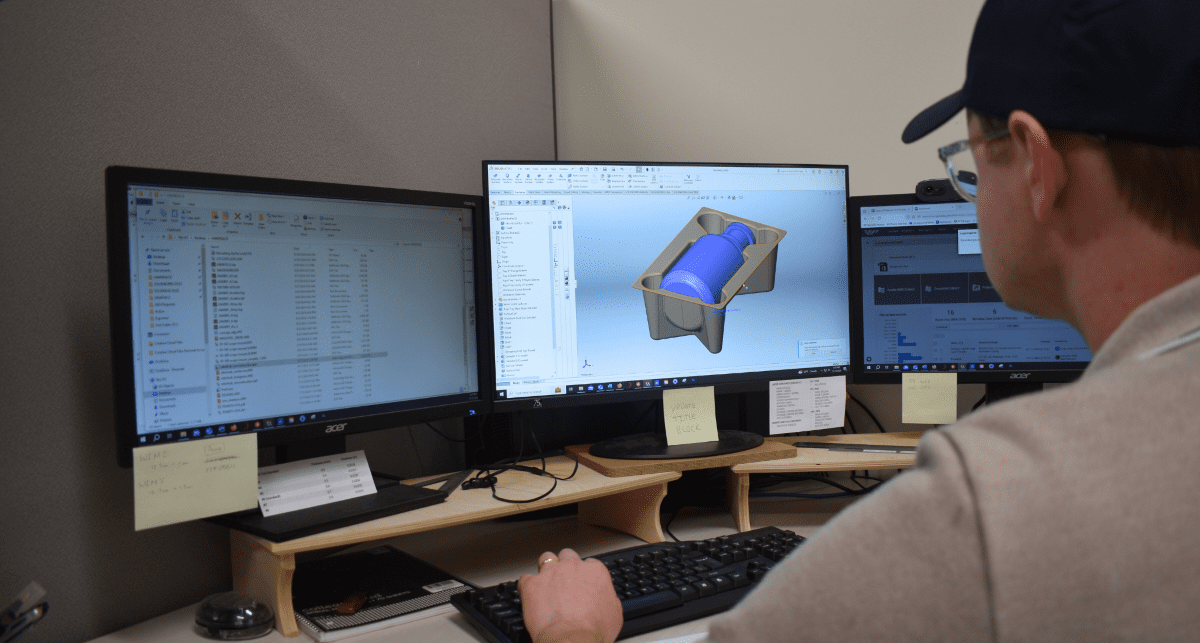

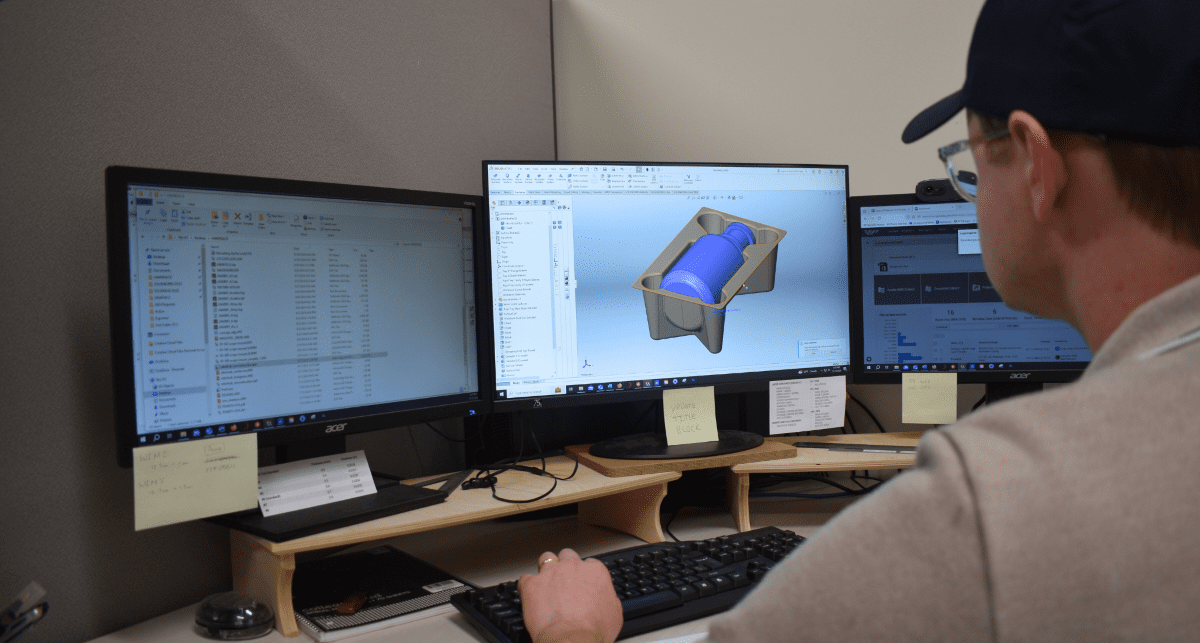

Designed to protect products, traditional packaging inserts are typically made from synthetic materials such as thermoformed plastic or styrofoam, which contribute to environmental waste and pollution. There are several eco-friendly alternatives that provide the same level of protection while offering sustainability:

- Molded Pulp Inserts: Made from recycled paper fibers, molded pulp provides excellent product protection while being biodegradable and recyclable.

- Paperboard and Corrugated Inserts: Made from renewable resources, these inserts offer a sturdy platform to hold products securely while being highly recyclable.

Optimizing Material Usage

Sustainable packaging design isn’t just about choosing the right materials—it’s also about using those materials as efficiently as possible. Strategies to optimize material usage can include:

- Efficient Sheet Utilization: Packaging structures can be designed to maximize the number of pieces on a sheet and minimize the amount of empty space between each piece, reducing scrap and material waste. For example, opting for a reverse-tuck folding carton instead of a straight-tuck design can often improve sheet yield, as the flap placement allows for more efficient nesting.

- Precise-Fit Packaging: Designing packaging that fits the product dimensions perfectly minimizes material usage.

Transportation Efficiencies

The weight and shape of packaging plays a significant role in carbon emissions during transportation. Efficient package design prioritizes:

- Lightweight Materials: Using lightweight materials such as paperboard or corrugated cardboard reduces fuel consumption and carbon emissions generated during transportation.

- Space-Saving Designs: Stackable packaging structures with minimal empty space inside maximizes shipping efficiency, allowing more products to be transported using less space and fewer resources.

Conclusion

By incorporating recycled, recyclable, and renewable materials into packaging designs, optimizing packaging structure, and reducing waste, brands can create packaging solutions that are both eco-friendly and functional.

At Wynalda Packaging, we are dedicated to helping businesses develop innovative, sustainable packaging solutions that align with their environmental goals. If you’re looking to make your packaging more sustainable, contact us to explore your options!