What Is FSC®-Certified Packaging, And Why Does It Matter?

More than ever, brands are being asked to back up their sustainability claims with proof. For packaging, one of the most trusted certifications is FSC® certification, a globally recognized standard for responsible forest management. But what does FSC-certified packaging really mean, and why should brands care?

The Forest Stewardship Council® (FSC)

The Forest Stewardship Council (FSC) is an international nonprofit that sets rigorous standards for responsible forestry. Their mission is to ensure that forests are managed in ways that prevent deforestation, preserve biodiversity, and benefit local communities and workers.

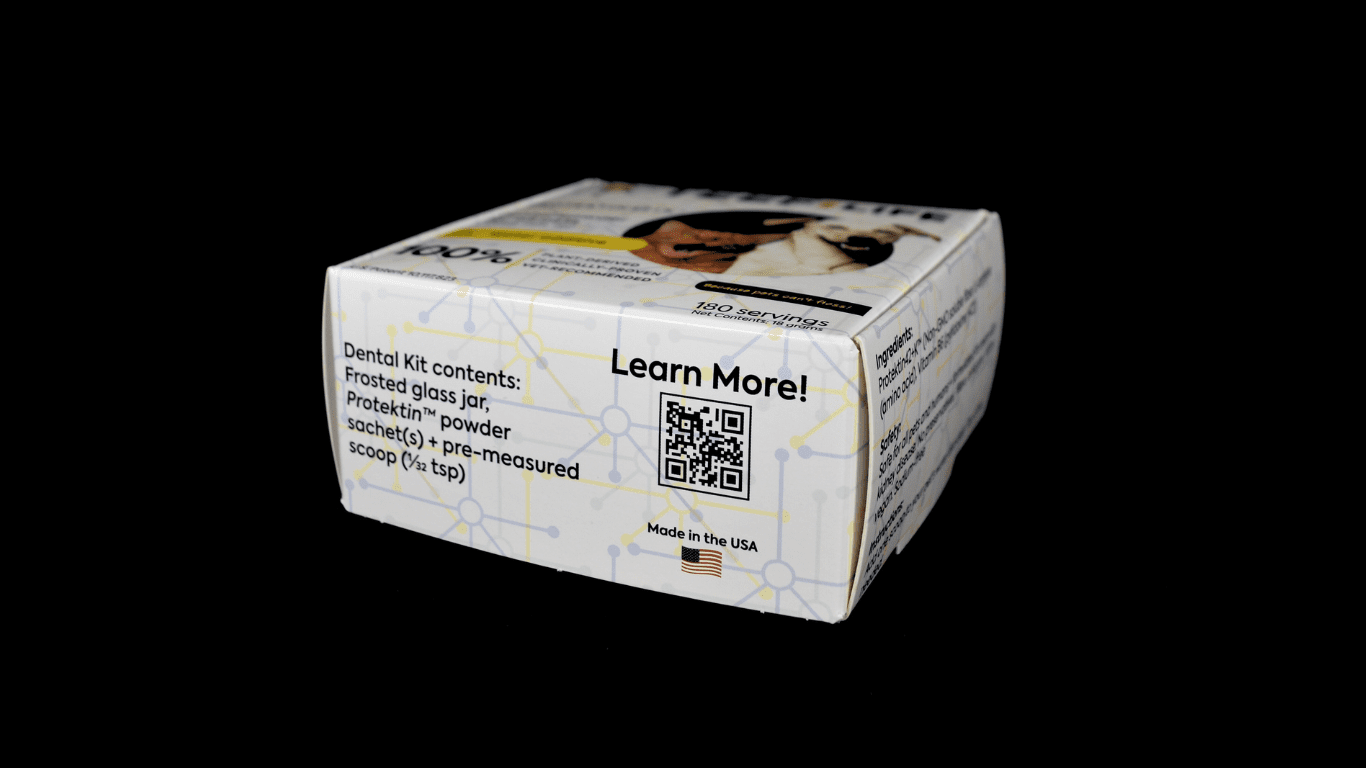

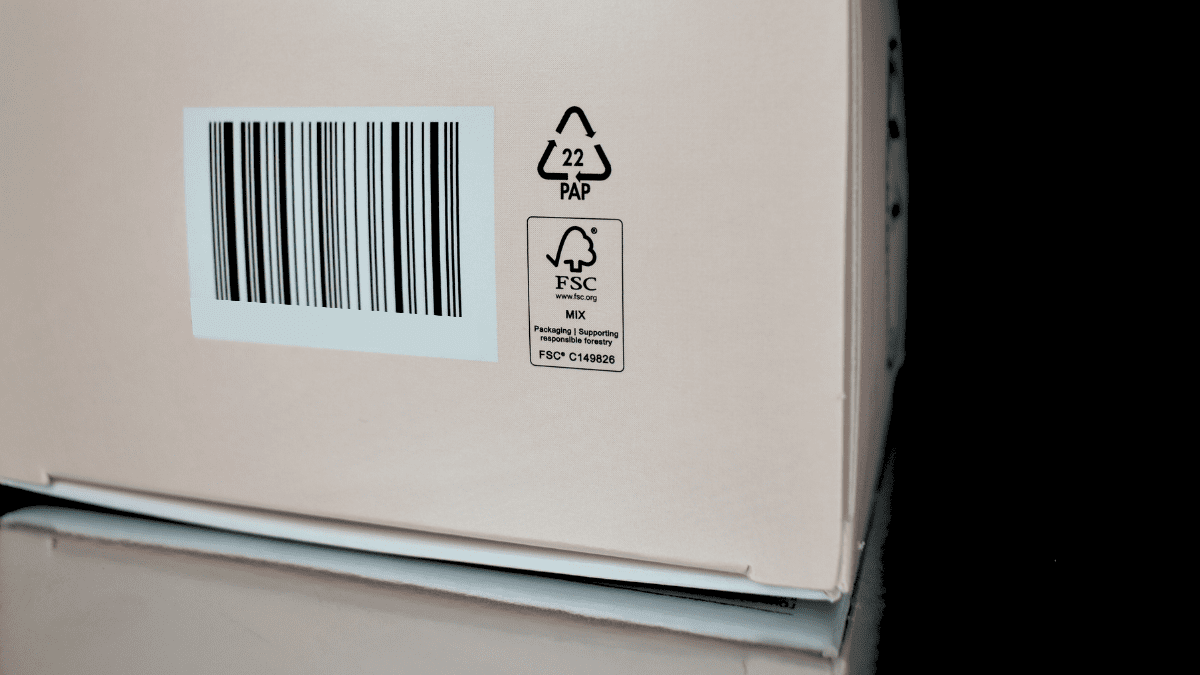

When you see the FSC label on packaging, it signals that the materials used support responsible forestry and come from verified supply chains.

FSC® Chain of Custody (COC)

The FSC Chain of Custody certification tracks forest-based materials through every step of the supply chain, from sourcing to distribution:

- Wood is gathered from responsibly managed forests and other controlled sources.

- The wood is processed into paperboard.

- That paperboard is converted into packaging.

- Packaging is supplied to brands and distributed to retail markets.

Every step in the supply chain is verified to ensure compliance with the FSC COC standards:

- Zero Deforestation – Trees are harvested responsibly, with no net forest loss over time. Old-growth and high-value forests are preserved.

- Fair Wages & Work Environments – Workers receive training, safe conditions, and fair compensation.

- Plant & Animal Protection – Biodiversity is safeguarded, protecting species that rely on forest habitats.

- Community Rights – Local communities are consulted, and their legal and cultural rights are respected.

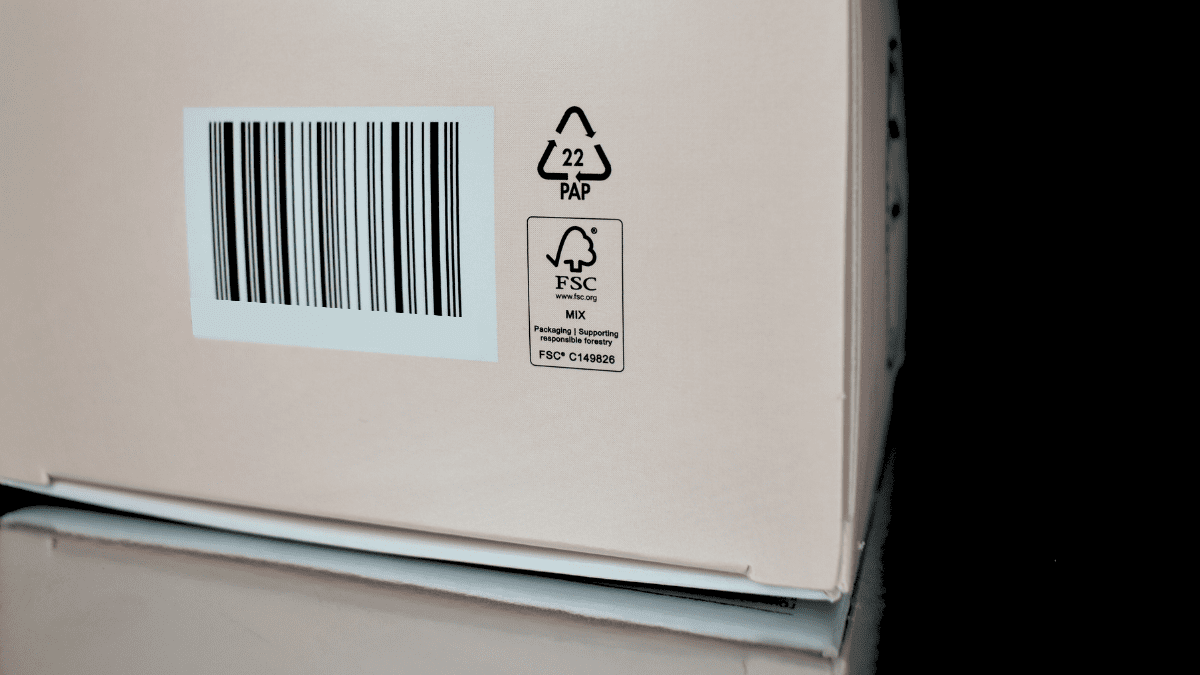

Types of FSC Labels

There are three main FSC labels you’ll find on packaging:

- FSC 100% – All materials come from FSC-certified forests.

- FSC Recycled – The product is made entirely from verified recycled material.

- FSC Mix – A combination of FSC-certified forest materials, recycled content, or controlled wood.

Each label communicates a clear story about the product’s sustainability.

Why Should Brands Use FSC-Certified Packaging?

- Environmental Responsibility – Supports climate initiatives, corporate sustainability goals, and global conservation efforts.

- Consumer Demand – Modern consumers are paying closer attention to eco-labels when making purchasing decisions.

- Reputation & Trust – The FSC logo is the most trusted mark in sustainable forest management, recognized by 56% of consumers worldwide. It helps brands stand out as credible and responsible.

FSC-Certified Packaging at Wynalda

At Wynalda, we’re proud to offer FSC-certified packaging solutions (FSC® C149826). Our certification means:

- Sourcing – We work with mills and suppliers that meet FSC requirements.

- Material Separation – FSC-certified materials are tracked and kept separate to maintain integrity.

- Audits – Regular third-party audits ensure compliance and accountability.

For our customers, this means peace of mind: when you choose Wynalda, you can confidently communicate your sustainability efforts to your customers.

The Bottom Line

FSC-certified packaging tells your customers that your brand values the environment, ethical practices, and long-term sustainability. By choosing FSC packaging, you’re not only protecting forests, you’re also building trust and credibility with consumers.

To learn more about FSC certification, visit www.fsc.org.