Child-Resistant Packaging

What Is Child-Resistant Packaging?

Child-resistant (CR) packaging is designed to be significantly difficult for children under the age of five to open within a set period of time. The goal is to prevent most young children from accessing the contents during a short testing window, while ensuring adults can still open and properly close the package.

Child-Resistant vs. Child-Proof Packaging

The term “child-proof packaging” is often used in conversation, but it is not a recognized regulatory standard. The correct term is child-resistant packaging, which reflects the true intent of these designs. No package is completely “child-proof.” Child-resistant designs are created to delay access and reduce risk, not eliminate it.

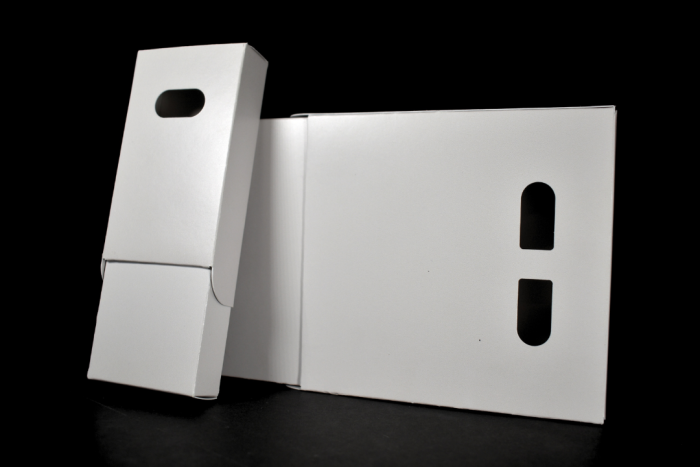

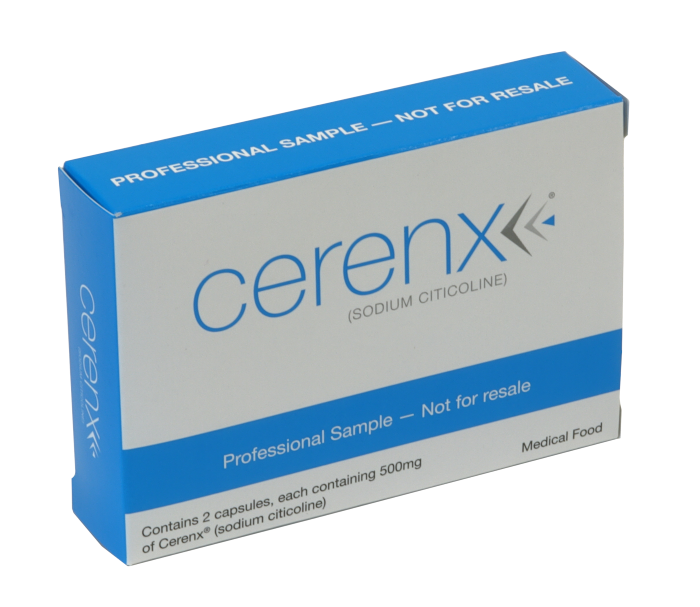

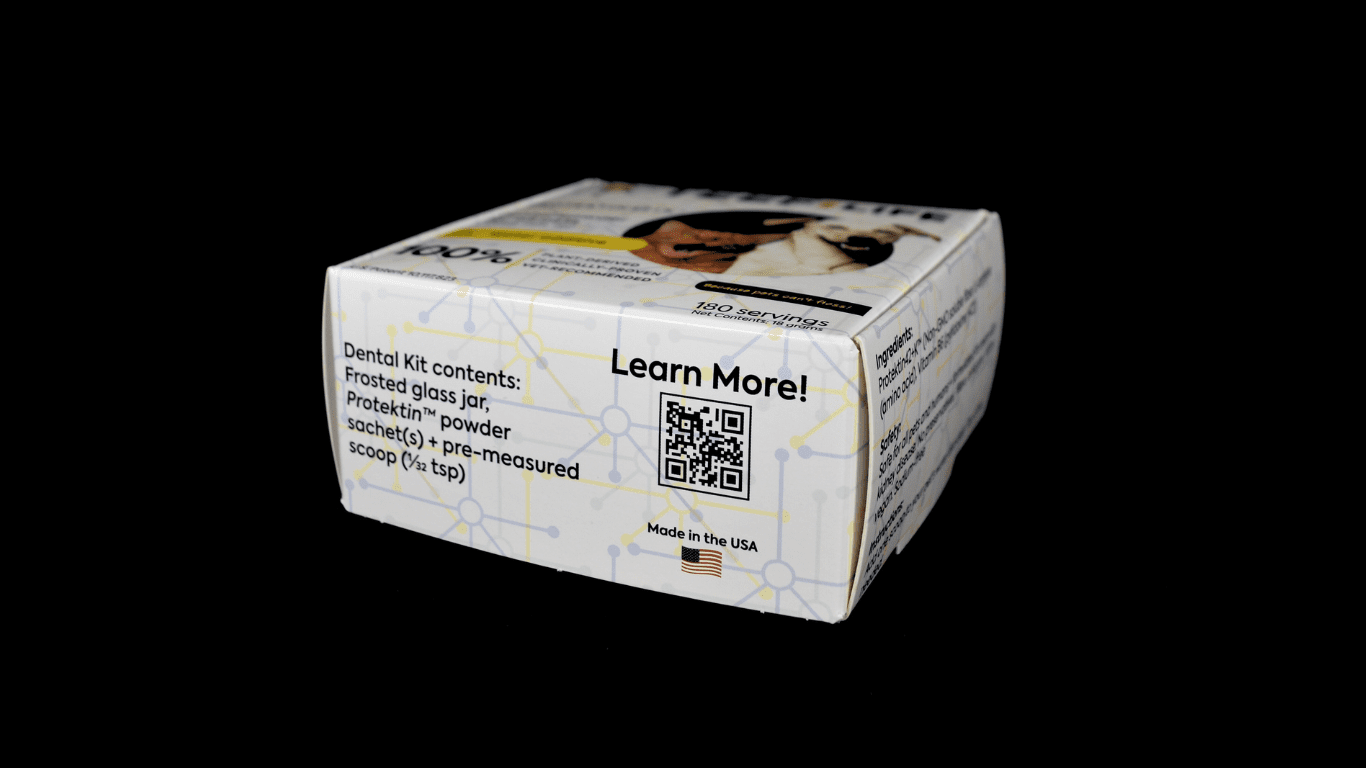

Child-Resistant Cartons

CR packaging is not limited to bottles and caps. Folding cartons can also be engineered with integrated safety mechanisms.

Common child-resistant box designs include:

- Push-and-slide trays requiring pressure at a specific location

- Locking tabs that must be engaged simultaneously

- Multi-step opening sequences

- Hidden release points combined with structural resistance

These designs rely on coordinated movements that are difficult for young children to execute, but intuitive for adults once understood.

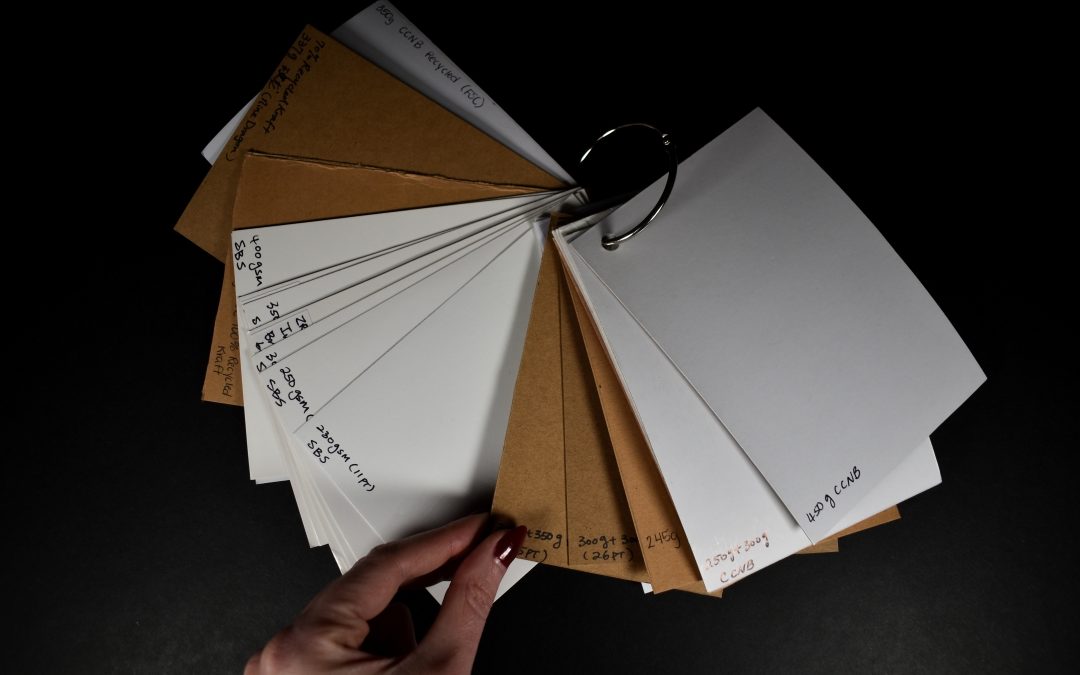

Because the mechanism is built into the structure, precise engineering, board selection, and manufacturing consistency are critical.

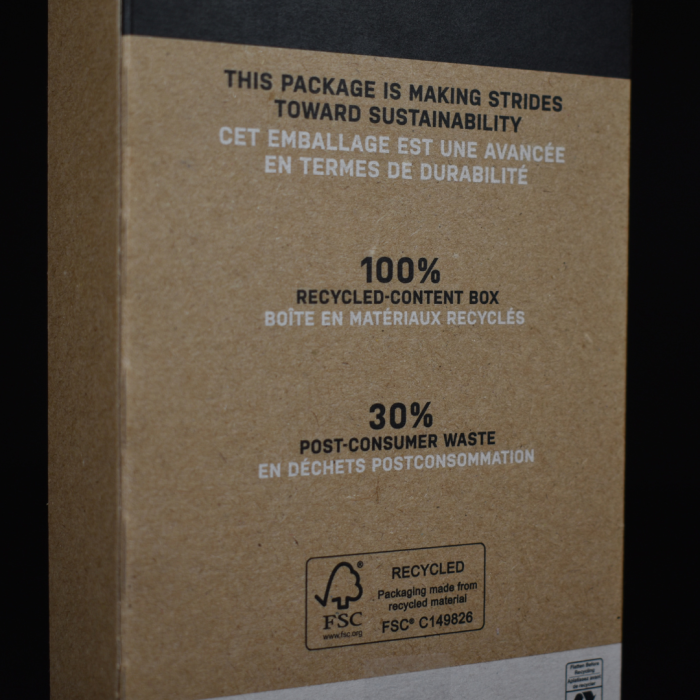

Industries That Use CR Packaging

Several industries rely on child-resistant packaging to meet regulatory requirements and reduce liability risk:

- Cannabis products

- Nicotine and vaping products

- Pharmaceuticals (prescription and OTC)

- Certain cosmetics and personal care items

- Household chemicals

As regulatory oversight expands—particularly in emerging markets like cannabis—CR packaging has become a critical component of compliance strategies.

How CR Packaging Is Certified

Certification of child-resistant packaging involves standardized, third-party testing protocols. In the United States, performance requirements are regulated by the U.S. Consumer Product Safety Commission (CPSC) under the Poison Prevention Packaging Act (PPPA). Packaging must meet specific performance thresholds that demonstrate it is challenging for young children to open within a reasonable timeframe, yet usable for adults.

Child Panel Testing

Children between 42 and 51 months of age participate in controlled testing. They are given a limited amount of time to attempt to open the package without instruction. If unsuccessful, they may receive a demonstration and a second opportunity. To pass, a high percentage of children must be unable to open the package within the initial test period, and a certain percentage must still be unable to open it after demonstration.

Senior Adult Testing

Adults typically between ages 50 and 70 are tested to confirm the packaging is not overly difficult for its intended users. To pass, a large majority of adults must be able to open and properly reclose the package within the specified time frame. This testing ensures safety does not come at the expense of accessibility.

Independent Laboratory Evaluation

Testing must be performed by an accredited third-party laboratory. Internal testing alone is not sufficient for regulatory compliance.

Documentation and Compliance Requirements

Once a package successfully passes testing:

- A General Certificate of Conformity (GCC) is issued by the manufacturer

- Suppliers provide documentation tied to the specific system tested

- Detailed records must be retained in case of regulatory review or investigation

Compliance applies to the exact configuration tested. Any modification to board grade, structural dimensions, closure components, or manufacturing tolerances could affect performance and invalidate prior certification. This is why early engineering alignment and production consistency are critical.

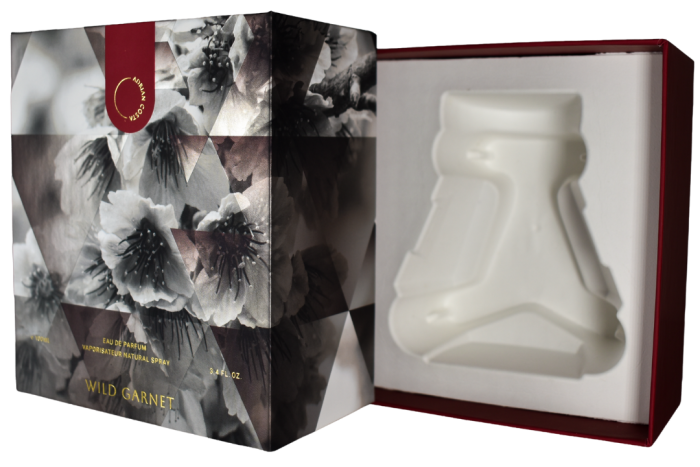

Designing for Safety and Manufacturability

Developing effective child-resistant packaging requires balancing:

- Regulatory compliance

- Consumer usability

- Brand presentation

- Production efficiency

It is not simply about adding a locking feature. It’s about designing an integrated system that performs reliably at scale.

For brands operating in regulated categories, investing in properly engineered and certified child-resistant packaging protects consumers, supports compliance, and reduces risk exposure.

Need a Custom CR Packaging Solution?

If you’re exploring CR options for your product, our packaging engineers can develop a custom solution tailored to your product and industry requirements.

Get the conversation started today!