Cold Foil Boxes for Don Julio

The Challenge

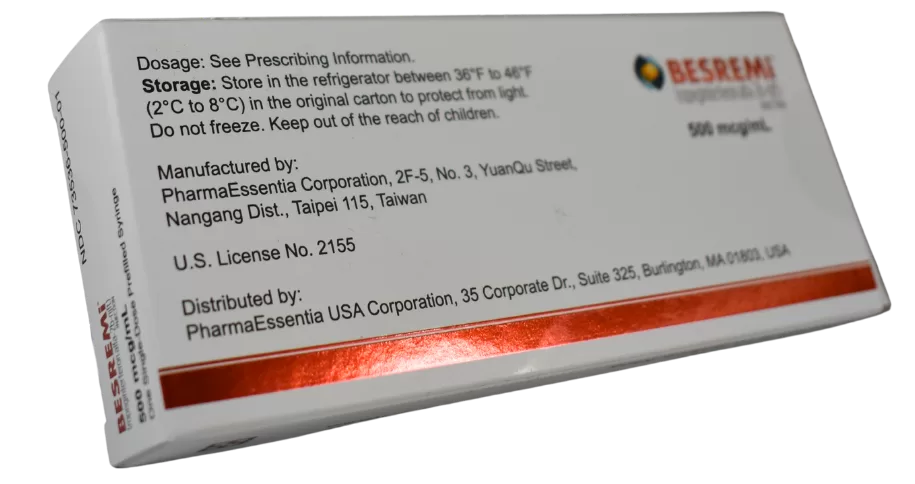

PharmaEssentia, a Taiwan-based pharmaceutical company, works to redefine the potential of proven therapies to enhance the health and quality of life for patients living with hematologic diseases. In 2017, they expanded into the U.S. market and began the rigorous process of obtaining FDA approval for their product. This process demanded production-quality printed packaging samples for each submission, and multiple revisions were expected. Therefore, PharmaEssentia relied heavily on Wynalda to quickly produce these samples to keep the approval process on track.

In addition to navigating the FDA’s requirements, PharmaEssentia aimed to redesign their product packaging for enhanced functionality and improved customer experience. The original packaging consisted of a simple reverse tuck carton and a paperboard insert. The insert lacked sturdiness and did not provide the desired unboxing experience, and the external design was minimalistic, featuring only a logo and black text. Since this packaging would be consumer-facing, PharmaEssentia sought to elevate the design with refined details to create a more positive user experience.

Specialty Coatings

Metalized Paperboard

Thermoformed Tray

The Solution

Wynalda began by replacing the paperboard insert with a thermoformed tray, significantly enhancing the syringe’s security and improving the overall customer experience. The trays are crafted from a 30 pt PETE medical blue material, which is 100% recyclable, and they are produced in an FDA-approved cleanroom. The cartons were sized to hold both the thermoform tray as well as a separate insert detailing the instructions for use.

To elevate the visual appeal of the packaging, Wynalda encouraged the use of 18pt MPET to give the box a sophisticated metallic shine. The boxes are printed with two coats of white, followed by a four-color process and a custom green PMS color. A soft-touch coating and spot gloss are applied to provide a premium finish.

Throughout the FDA approval process, Wynalda manufactured multiple small production runs, quickly producing new samples to meet the stringent requirements and tight deadlines. Wynalda’s Design and Prepress teams remained deeply involved, making numerous adjustments to ensure the packaging met all FDA criteria.

The Result

Wynalda’s responsiveness and speed-to-market enabled PharmaEssentia to maintain momentum throughout the FDA approval process, allowing their therapies to reach patients within the U.S. market as quickly as possible. The redesigned packaging was a success, enhancing both functionality and customer experience. PharmaEssentia was very pleased with the new packaging and very appreciative of Wynalda Packaging’s responsiveness to their demands.

“Wynalda has been an amazing partner. They have always taken our needs as a business very seriously, from the point when we were pre-commercial all the way until now. They do business honestly, they do what they say they are going to do, and they are amazingly reliable, predictable, and flexible.”