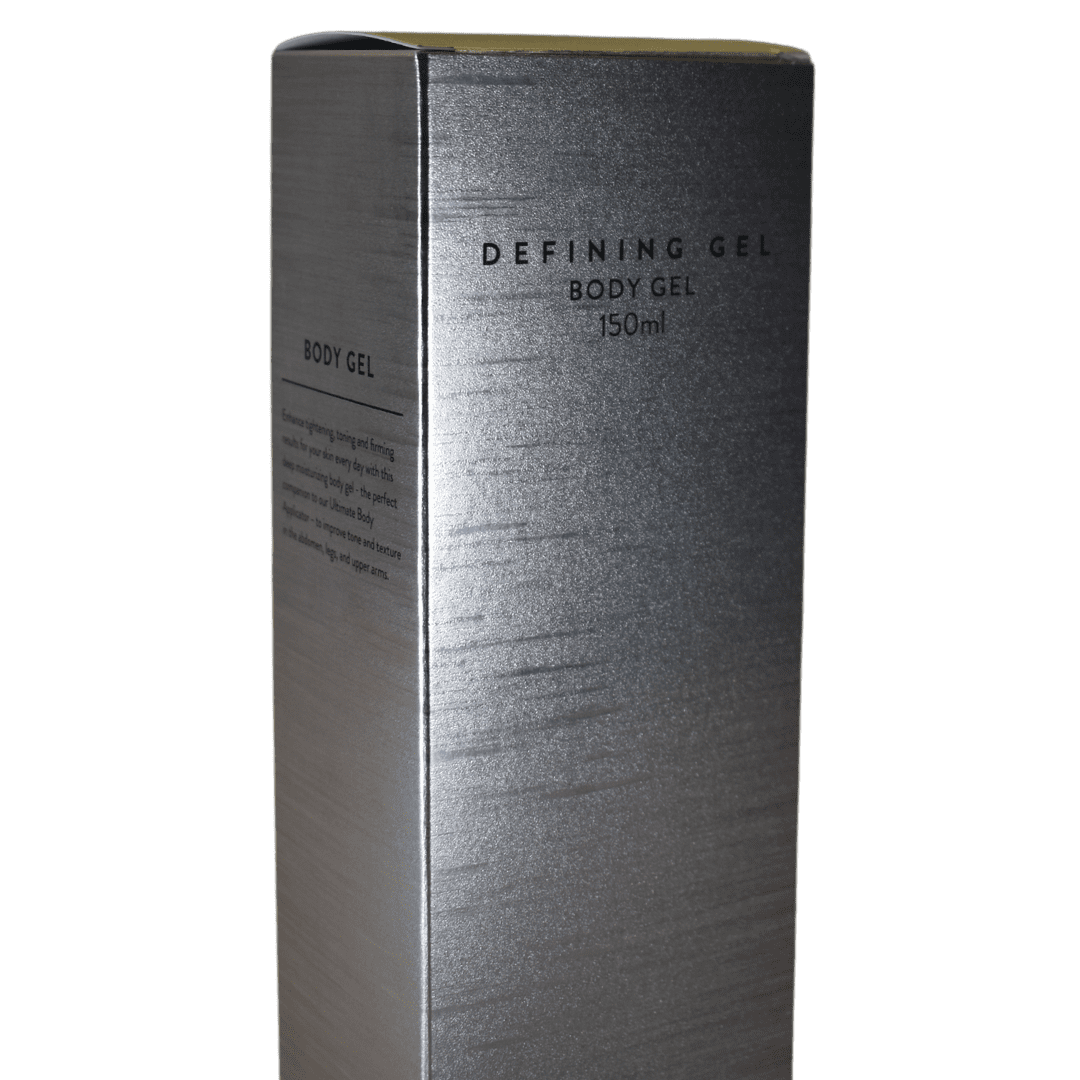

Packaging Enhancements

Our packaging enhancements allow us to create distinctive, high-impact packaging that builds consumer confidence and adds value to every brand we serve.

SPECIALTY COATINGS

COLD FOIL APPLICATION

HOT FOIL STAMPING

EMBOSSING & DEBOSSING

WINDOWING

MAGNET CLOSURE

SERIALIZATION & INK JETTING

Specialty Coatings

Specialty UV & aqueous coatings can be applied during printing to enhance both the visual appeal and functionality of packaging. Some of the most commonly used specialty coatings at Wynalda Packaging include: gloss, matte, soft-touch, pearlescent, reticulating, and spot UV.

Whether using just one, or combining multiple specialty coatings, they can be used to add depth, texture, and protection to packaging, helping brands achieve a distinct, high-quality finish tailored to their unique needs and marketing position.

Cold Foil Application

Applying cold foil as part of the printing process enhances printed packaging with metallic effects, adding a luxurious, eye-catching finish. In cold foil printing, adhesive is applied in the desired locations while on press and metallic foil is transferred onto the adhesive. This method allows for fine details, intricate patterns, and vibrant colors, as the foil can be overprinted with inks to create a wide range of metallic hues.

Commonly used on packaging for cosmetics, luxury goods, and high-end consumer products, cold foil helps create a premium look that stands out on the shelves. Additionally, cold foil is more eco-friendly compared to traditional hot foil stamping, as it typically generates less waste and is applied in-line during the printing process, streamlining production.

Hot Foil Stamping

Hot foil stamping is a process where metallic foil is applied to packaging, creating a high-quality, reflective finish that adds elegance and distinctiveness to the product, grabs attention, and enhances your product’s perceived value.

Hot foil stamping offers a wide range of foils including golds, silvers, holographic foils, and extensive color options. It can be combined with embossing to create a raised, tactile feel, further enhancing the sense of quality. Though it’s more time intensive than cold foiling, hot foil stamping delivers unmatched depth, texture, and durability, making it a popular choice for premium packaging.

Beyond aesthetics, foil stamping also serves as a powerful security feature. Integrating security elements within the foil can ensure product authenticity, reassuring customers that they have the genuine item, not a counterfeit.

Embossing & Debossing

Embossing and debossing are two techniques in packaging manufacturing used to add depth, texture, and tactile elements to designs, enhancing both visual and physical appeal. At Wynalda, we offer a range of embossing and debossing options.

Embossing creates a raised effect, making specific design elements such as logos or patterns stand out. Embossing is often combined with other finishes such as specialty coatings or hot foil stamping to further accentuate the raised elements, adding a luxurious touch and making the packaging more engaging.

Debossing creates a recessed effect by pressing the design into the packaging’s surface. Debossing provides a subtle, sophisticated look that emphasizes detail and depth without necessarily catching light as embossing does. It can be used alone or paired with matte or gloss finishes to create contrast.

Windowing

Incorporating windows into the packaging’s design allows consumers to see the product inside without opening the package. This design feature is highly effective in boosting product appeal and building consumer trust.

The use of windows in packaging serves several purposes, including product transparency, enhanced visual appeal, brand trust, and reduced need for imagery.

Wynalda Packaging developed Wynview™, a unique waterfall-style two-panel rigid window that provides an elegant display of the product from several angles.

Magnet Closure

Magnetic closures in folding cartons or rigid boxes adds a premium, innovative touch that enhances both functionality and aesthetics. Incorporating small magnets into the packaging creates a secure closure that offers several benefits, including enhanced consumer experience, reusability, and brand differentiation.

Serialization & Ink-Jetting

Serialization involves the application of unique identifiers such as serial numbers or redemption codes on each individual package, adding traceability and security across the supply chain. Our ink-jetting machine can also print barcodes or QR codes onto packaging.

Key benefits to serialization include: product authentication,

supply chain transparency, regulatory compliance, enhanced consumer engagement, quality control, and recall management.